Pioneer of geared motor / geared pump

TSUKASA ELECTRIC CO.,LTD

Precaution

- Protection against over current and locked rotor

- Cautions for low speed operation

- Electric noise filter

- Cautions for PWM control

- Cautions for continuous operation

- Over run and short brake

- Cautions for instant reverse

- Cautions for Installation

- Cautions for additional modifications

- Cautions for soldering

- Caution for power transmission

- Cautions for gear installation

- Operation & storage environment

- Shock and fall

- Input terminal

- Rotation from output shaft

- Life

Protection against over current and locked motor

If the load is in the range of rated load, generated heat and radiated heat become uniform and the temperature becomes stable at a certain degree. At this point, the motor winding would not be burnt.

However, the generated heat amount increases when the motor is overloaded or the stator is locked, and that conditions are kept, it causes that the winding insulation film melted and winding will be shorted each other. This is called layer short.

*To protect the motor from layer short, we recommend PoliSwitch by Littlfuse. (Resettable current protection)

*The table on the right shows the representative time from when the motor gets locked till layer short occurs.

| Time to layer short when a rotor is locked | |

|---|---|

| TG-47A、24V | Temperature saturation |

| TG-47B、24V | Temperature saturation |

| TG-47C、24V | 16.0分 |

| TG-06D、12V | 3.75分 |

| TG-06E、24V | 4.75分 |

| TG-85B、12V | 3.60分 |

| TG-85C、24V | 2.75分 |

| TG-85E、24V | 1.00分 |

| TG-01F、24V | Temperature saturation |

| TG-01G、24V | 4.25分 |

| TG-01H、12V | 5.75分 |

Cautions for low speed operation

Most DC motors have carbon brushes. There are two types of wear with the carbon brushes: mechanical wear by carbon brushes touching with commutators to rotate a motor, and some electrical wear by commutation spark.

If a motor is rotated with low speed, it may cause short-circuit because brush wear debris between the commutator. Be sure that this may cause motor burn or a driver burn.

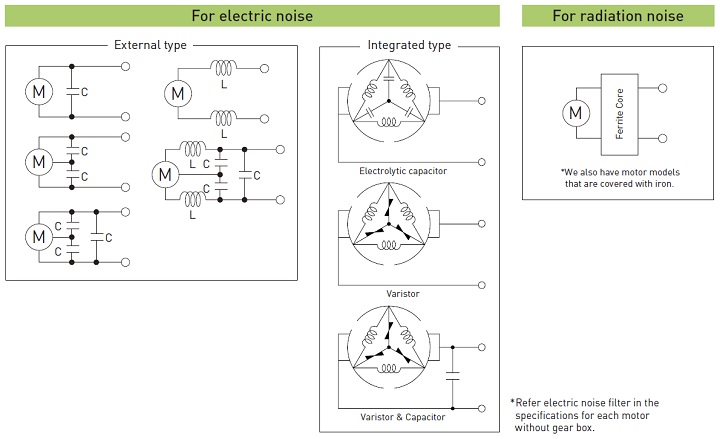

Electric noise filter

Noise reduction amount by the noise filter differs per motor type.

Be sure to evaluate the effect of noise reduction beforehand.

Cautions for PWM control

PWM operation may shorten the brush life compared to the conditions under the rated voltage and stable voltage. Depending on the frequency, it may accelerate carbon brush worn significantly.

Typical frequency of PWM control for a DC brushed motor is 10-20kHz. Repeating on and off, PWM control does save the energy, but it may cause heat by resonance depending on the motor parts and range of frequency.

Be sure to review the conditions by conducting thorough evaluation tests using actual applications before proceeding to your production.

* When driven in PWM at certain frequencies, it may occur that a motor does not start due to the combination of driving frequency and internally fitted capacitive noise suppressor. In that case, please select a motor with a varistor inside. Evaluation tests are still required.

Cautions for continuous operation

Select a gear head that is designed for continuous operation. If you use a gear head that is designed for intermittent operation for continuous operation, the sliding part, where a gear and shaft touch for example, will heat up and it may even cause burn at the worst case.

Locked Gear: The time until the burn would be different depending on the gear model and operation conditions.

Over run and short brake

Even after the power supply is turned off, motor rotors will rotate for a certain time by inertia. This is called over run.

As one of the common ways to stop the overrun immediately, you can use short brake which is applying a shortcircuit across the motor terminals when the power source is turned off.

*Be aware that using short brake may shorten brush life because it uses a generator action of a motor and the current value will temporarily rise.

Please refer representative values on the right side.

| Model |

Short circuit |

Open circuit |

|---|---|---|

| TG-47A、24V | 1.6 revolution | 8.9 revolution |

| TG-47A、24V | 2.5 revolution | 18.4回転 |

| TG-47C、24V | 4.0回転 | 29.4回転 |

| TG-06D、12V | 5.9回転 | 48.9回転 |

| TG-06E、24V | 3.8回転 | 49.0回転 |

Cautions for instantaneous reversing

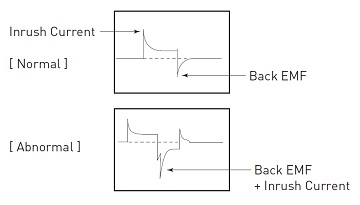

If the supply polarity to the motor is switched to reverse the rotation before the motor completely stops rotating, it will result in a very high instantaneous current until the motor is back to normal operation because the power that the motor generates, which is called back EMF, will be added to the current from the power source. This may cause driver damage or motor burn at the worst case.

Vertical mounting with shaft up

In some cases that a motor-gear is mounted with the shaft up, traces of lubrication oil can contaminate the brushes and commutator. This may result in shortening brush life or causing a short-circuit because it accelerates brush worn significantly when the oil reaches commutator.

To prevent this kind of accident, we offer an oil shield option for each motor. Please refer a page for product number explanation when you select the oil prevention option.

Each of geared motor products have mounting tap holes, or through holes for some products. Do not use long screws that would touch internal components when the geared motor is installed. Please refer tho the effective depth of the tap holes on our catalog when you select screws.

Cautions for additional modifications on our product

Any additional modification, to an output shaft for example, may damage the geared motor. It affects the product specifications due to loosened screws or dislocation of gears by shock load and / or vibration by any modification added to the product.

Cautions for soldering

Be sure that overheating of a soldering gun may melt the internal parts and damage the internal structure when you solder a wire to an input terminal of the motor.

Reference: Typically, we recommend 40W soldering iron with the iron tip controlled at 320 ± 20°C by a

temperature controller, soldering time 2-3 seconds.

Cautions for power transmission

Be sure not to apply any radial load higher than the allowance to the output shaft when you use a pulley, a belt chain, a warm gear, etc. to transmit the power from the motor.

Cautions for gear installation

Be sure about the following points when you install a pulley, gear etc. on an output shaft:

-Do not make adhesive touch a bearing of the gearhead if you mount any parts using adhesive.Be sure that volatile adhesive may damage commutators and cause faults on the motor.

- Do not apply thrust load higher than allowance on an output shaft when you press-fit any parts on the output shaft.

Operation & storage environment

Corrosion on components can be occurred and affect the specifications if the product is stocked and used in the environment out of allowable conditions.

Even if it is stored or used in the range of allowable conditions, storage for a long term, or depending on the

ambient environment, it may cause corrosion.

| Temprerature | Humidity | |

|---|---|---|

| Allowable operation environment conditions | -10 〜 +50℃ | 20〜90%(No condensation) |

| Allowable storage environment conditions | -20 〜 + 60℃ | 10〜95%(No condensation) |

Shock and Fall

If any shock such as fall is applied to the motor, it may cause damage of the parts, loosened screws, dislocation of gears etc. and it may cause a failure.

Input terminal

If any shock such as fall is applied to the input terminal, it may cause failures because the shock causes stress on the internal connection part which results in conduction failure.

Rotation from output shaft

Do not rotate our geared motor from the output shaft. It may break the gears.

Life

Please inquire to our sales department for life time of our products.